Product Description

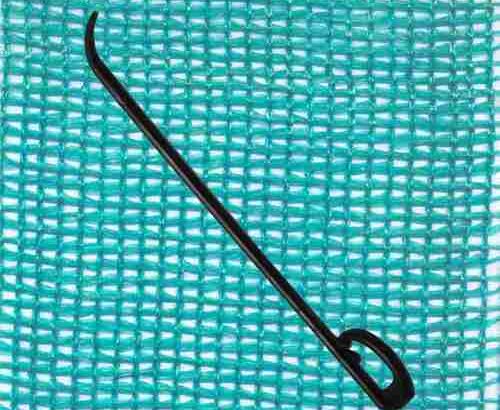

In Today’s Scenario We are using the best Net Stitching Stick in India & Continuously serving our customers. It is uses to joint more than one net and to make a Shade Net House is call, in other words Shade Net Pin also. Our Net Stitching Stick is durable & long-lasting.

Features:

- Easy to use

- Compact design

- High strength

- UV Stabilise

- Long Durability

Product Specification

| Material | Hdpe Plastic |

| Colour | Black |

| Usage/Application | Agriculture |

| Brand | Shri Ji |

| Length | Upto 6 Inch |

| Application | Greenhouse |

| Minimum Order Quantity | 2000 Pcs |

Additional Information

| Delivery Time | Same Day |

| Production Capacity | 2 Lake Piece |

| Packaging Details | Plastic Bag |

| Packing Qty | 500 Pcs |

| Payment Terms | Advance |

| Payment Mode | RTGS / NEFT / IMPS |

Introduction to Net Stitching Sticks

Net stitching sticks are specialize tools use for stitching and repairing nets, such as fishing nets, sports nets, or other types of netting. They are design to make the process of net repair more efficient and effective.

Net stitching sticks typically have a long, slender shape with a point end and a hook or eyelet on the other end. The sharp end is uses to pierce through the net material, creating holes for the stitching thread or twine to pass through. The hook or eyelet holds and guides the thread during the stitching process.

These stitching sticks are made from durable materials such as metal or sturdy plastic to withstand the tension and pressure apply during the net repair. They come in various sizes and designs to accommodate different netting materials and mesh sizes.

Net stitching sticks are essential in fishing, sports, and agriculture industries, where nets are uses extensively and often require regular maintenance and repair. They enable users to mend tears, reinforce weak areas, and extend the lifespan of nets, ensuring optimal performance and functionality.

By using a net stitching stick, individuals can achieve precise and consistent stitches, resulting in strong and secure repairs. This tool simplifies the process of net repair, making it more accessible to individuals with varying levels of experience.

Whether it’s repairing fishing nets for commercial fishermen, sports nets for athletes, or protective nets in agriculture, net stitching sticks play a crucial role in maintaining the integrity and functionality of nets, prolonging their usability, and contributing to the overall efficiency of various industries.

Different Types of Net Stitching Sticks

Several different types of net stitching sticks are available, each design for specific purposes and suits to different types of netting materials. Here are some of the common types of net stitching sticks:

- Essential Stitching Stick: This is the most common type of net stitching stick. It features a long, slender shape with a points end for piercing through the net material and a hook or eyelet on the other end for threading the stitching thread or twine. Basic stitching sticks are versatile and can be use for a wide range of net repair applications.

- Shuttle Stitching Stick: Shuttle stitching sticks have a slightly different design than basic stitching sticks. They have a shuttle-like shape, often made of plastic or lightweight materials, with a point end for piercing the net and a groove along the length to hold the stitching thread or twine. The track allows the thread to unwind smoothly during the stitching process, making it easier to control and maintain tension.

-

Palm Stitching Stick: Palm stitching sticks are design to be held and controlls with the hand, resembling a small handheld tool. They usually have a pointed tip for piercing the net and a handle or grip for better control. Palm stitching sticks are handy for intricate or detailed net repairs where precision is important.

- Electric Stitching Stick: Electric stitching sticks are power by electricity and offer automates stitching capabilities. They have a motorizes mechanism that pierces the net and stitches it automatically. Electric stitching sticks are often use in industrial settings or for high-volume net repairs where efficiency and speed are crucial.

- Customized Stitching Sticks: Depending on the specific application or industry, customize net stitching sticks may be available. These sticks are tailor to meet specific requirements, such as extra-long or extra-strong stitching sticks for large nets, specialize shapes for unique netting materials, or additional features for specific repair techniques.

When choosing a net stitching stick, it’s important to consider factors such as the type of net being repaire, the desire stitch style, the material of the stitching stick, and the user’s level of experience. Selecting the right stitching stick for the job can help ensure efficient and effective net repairs.

Materials Used in Net Stitching Sticks

Net stitching sticks are typically made from durable materials that can withstand the pressure and tension apply during the net repair. Here are some of the common materials use in the construction of net stitching sticks:

- Metal: Metal, such as stainless steel or aluminum, is a popular material choice for net stitching sticks. It offers strength, rigidity, and durability, making it suitable for heavy-duty repairs. Metal stitching sticks are resistant to bending or breaking under tension, providing reliable performance for long-lasting use.

- Plastic: Various types of plastic, such as nylon or high-density polyethylene (HDPE), are commonly used in net stitching stick manufacturing. Plastic sticks are lightweight, affordable, and easy to handle. They are less likely to damage or scratch the netting material during repair.

-

Fiberglass: Fiberglass stitching sticks are lightweight and strong, making them a popular choice for net repairs. They are resistant to corrosion and can withstand exposure to moisture or harsh environmental conditions, making them suitable for marine or outdoor applications.

- Carbon Fiber: Carbon fiber stitching sticks offer a high strength-to-weight ratio and excellent rigidity. They are lightweight yet extremely strong, providing optimal control and precision during the net repair. Carbon fiber sticks are often use in professional or specialize netting applications.

- Wood: Although less common, wooden stitching sticks can still be found. They are typically made from hardwood or durable wood materials. Wood sticks offer a traditional and natural feel and can be customized or shaped for specific repair requirements.

The choice of material for a net stitching stick depends on factors such as the type of net being repaired, the required strength, the desired weight, and the user’s personal preference. Each material has its advantages and considerations, and it’s important to select a stitching stick that matches the specific needs of the net repair task at hand.

How to Use a Net Stitching Stick

Using a net stitching stick is a straightforward process once you understand the basic steps involved. Here is a general guide on how to use a net stitching stick for net repair:

- Gather the necessary materials: Before starting, gather the net stitching stick, stitching thread or twine, and the net that needs to be repaired. Ensure you have the appropriate thread or twine matching the netting material and the stitching stick.

- Identify the damaged area: Locate the tear, hole, or damaged section of the net that needs to be repaired. Assess the size and extent of the damage to determine the appropriate stitching technique.

- Prepare the stitching stick: If your stitching stick has an eyelet or hook, thread the stitching thread or twine through it. Ensure that there is enough thread to complete the repair without running out.

- Pierce through the net: Starting from the backside or underside of the net, insert the pointed end of the stitching stick through the mesh near the edge of the damaged area. Push the stick through the netting, creating a hole for the thread to pass through.

-

Thread the stitching thread: Once the stitching stick has pierced through the net, use the hook or eyelet on the stick to catch the stitching thread or twine. Pull it through the hole you created, leaving a small tail of thread on the underside of the net.

- Stitch the net: Choose an appropriate stitching technique depending on the size and type of damage. Common techniques include simple over-and-under stitches, double stitches, or specific patterns for reinforced repairs. Refer to net repair guides or tutorials for detailed stitching techniques relevant to your specific netting material.

- Repeat the stitching process: Continue inserting the stitching stick through the net, creating holes, and threading the stitching thread or twine. Follow the stitching technique appropriate for your repair until you have covered the entire damaged area.

- Tie off the stitching: Once the repair is complete, tie off the stitching thread or twine on the underside of the net using a secure knot. Trim any excess thread or twine to neaten the repair.

- Test the repair: After completing the stitching, inspect the repair to ensure that it is secure and properly aligned. Test the strength of the repair by gently pulling on the net around the repaired area.

With practice and experience, you will become more proficient in using a net stitching stick and choosing the appropriate stitching techniques for different types of net repairs. Remember to follow safety precautions, work in a well-lit area, and use the correct materials and techniques for optimal results.